PRODUCT VIDEO

PRODUCT INTRODUCTION

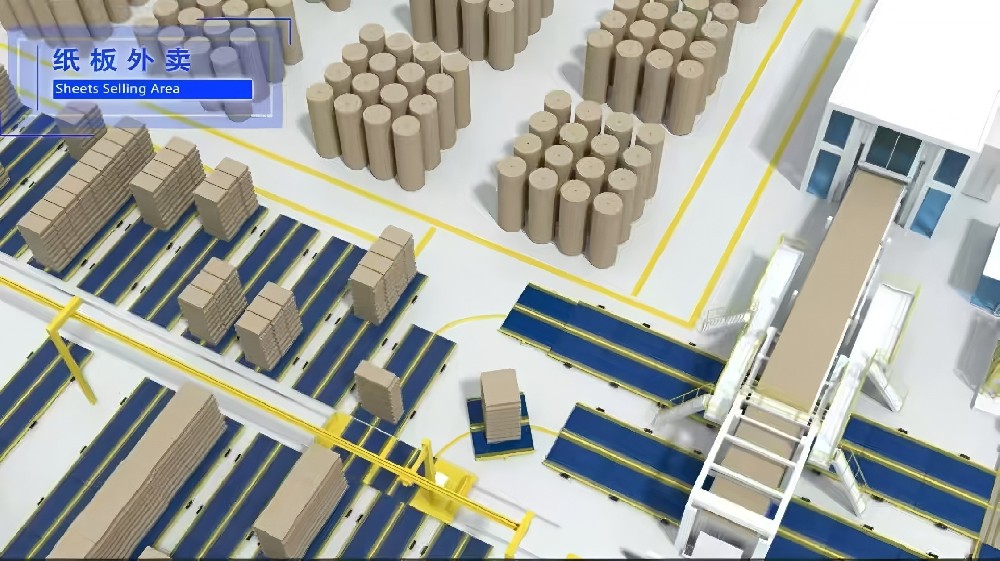

Corrugated Carton Conveyor System

In the Era of Digital Transformation and Smart Manufacturing Under the tide of digital transformation and smart manufacturing, Wist smart is committed to reshaping the new ecosystem of intelligent logistics, driving the manufacturing industry towards higher efficiency and greater intelligence. With technological innovation at our core, we provide customers with comprehensive, end-to-end intelligent logistics solutions, helping enterprises achieve seamless integration of production and logistics, and enhancing overall operational efficiency.

Core Technologies

Intelligentization: Through advanced software systems and automated equipment, we enable intelligent management of the entire logistics process.

Integration: By consolidating upstream and downstream data, we build a full-chain intelligent logistics system from raw materials to finished products.

Flexibility: We offer scalable and adaptable solutions to meet the needs of multi-variety, small-batch production needs.

Smart Factory Planning and Layout: Leveraging extensive industry experience, we provide tailor-made smart factory solutions to achieve high-level coordination between production and logistics.

Upgrading and Retrofitting Old Factories: We assist traditional manufacturing enterprises in completing intelligent upgrades, enhancing production efficiency and competitiveness.

PRODUCT DETAIL

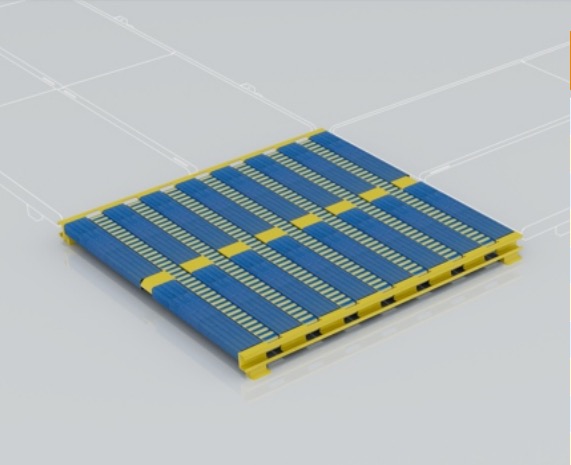

Plastic Modular Conveyor

Modular Material: Plastic modular conveyor belt made of POM material, with a belt thickness of 12.5mm. Modular Support: High molecular weight polyethylene wear-resistant strips + high-quality multi-layer board support. Equipment Material: 4mm Q235A hot plate laser cut and bent, with surface treatment of paint or spray treatment. Support Feet: Square tube cut and welded, made of Q235A plate welding, adjustable height ±50mm. Motor Power: 1.5KW-4.5KW Motor Brand: Guomao, China. Load Capacity: 2500KG/unit. . Frequency conversion control, maximum 25m/min. Control Program: Self-developed PLC program for automatic control, with photoelectric switch at the end of the conveyor for anti-fall protection

Trunsfer Shuttle Car (Single/ Dauble Decker)

modular Material: Plastic modular conveyor belt made of POM material, with a belt thickness of 12.5mm. Conveying Power: Conveying motor 2.2KW, traveling motor 3.7KW*2. Vehicle Speed: Conveyor belt speed maximum 25m/min, vehicle traveling speed maximum 120m/min. Motor Brand: Guomao, China. Frequency Converter: Inovance, China. Casters: Guide Rail: Rail surface made of cold-drawn steel welded together, requiring secondary conereate, with the rail level with the ground. Control Program: Self-developed PLC program for automatic control, and manual cortrol. Safety Device: Equipped with a SICK 270° fan-shaped laser scanner. If a person enters the scanning area within a 2-5 meter range, the shuttle car will decelerate and stop, effectively ensuring personnel safety

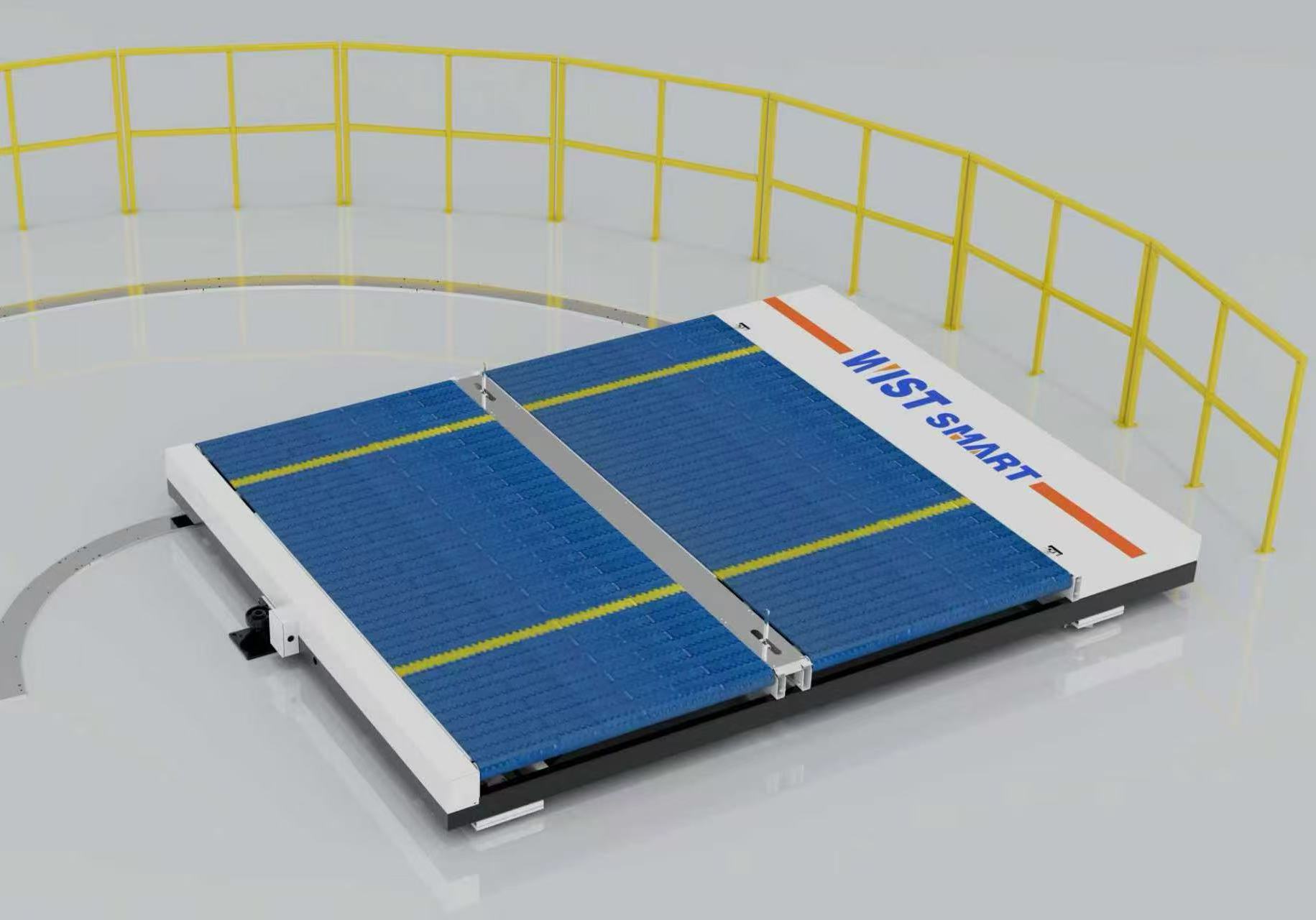

Cross Conveyor (XY)

modular Material: Utilizes a plastic modular conveyor belt made of POM material, with a belt thickness of 12.5mm. Modular Support: Polyurethane backing plate. Motor Power: 2.2KW for the X-axis direction, 3.0KW for the Y-axis direction. Motor Brand: Guomao, China. Lifting Mechanism: Airbag lifting with a pneumatic pressure of 6KG. Equipment Material: Constructed from welded steel sections. Side Panels: 10mm Q235A plate laser cut and bent, with surface paint or spray treatment. Transmission Method: Chain linkage structure to guarantee an excellent transmission performance. Conveying Speed: Frequency conversion control, with a maximum speed of 25m/min. Load Capacity: ≤500 KG/M².

Fully Automatic Stream Extractor

Constructed using bent and welded steel plates, this machine treats paper stacks by blowing air on one side and suctioning on the other, ensuring a more uniform and moderate moisture content within the paperboard.

The fan units on both sides are suspended in the air via a gantry frame, allowing for distance adjustments based on the paperboard specifications.

It offers the flexibility to manually set dehumidification parameters and duration, or to integrate with production management systems for automated control.

Plastic Modular Conveyor

Modular Material: Plastic modular conveyor belt made of POM material, with a belt thickness of 12.5mm. Modular Support: High molecular weight polyethylene wear-resistant strips + high-quality multi-layer board support. Equipment Material: 4mm Q235A hot plate laser cut and bent, with surface treatment of paint or spray treatment. Support Feet: Square tube cut and welded, made of Q235A plate welding, adjustable height ±50mm. Motor Power: 1.5KW-4.5KW Motor Brand: Guomao, China. Load Capacity: 2500KG/unit. . Frequency conversion control, maximum 25m/min. Control Program: Self-developed PLC program for automatic control, with photoelectric switch at the end of the conveyor for anti-fall protection

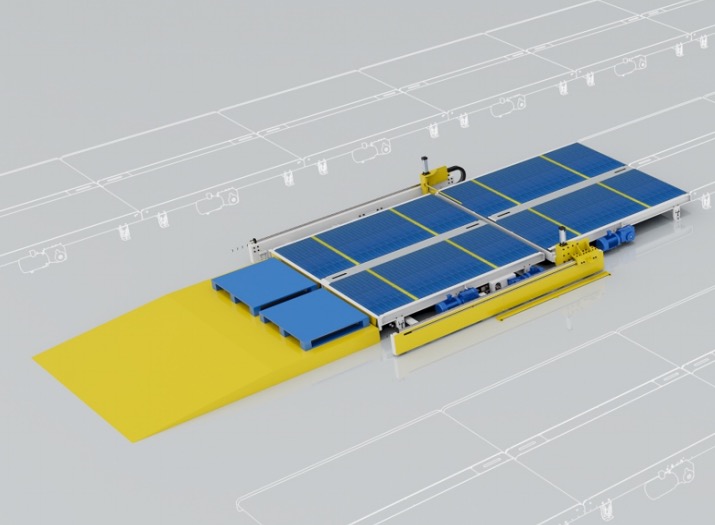

Scraper-type Automatic Pallet Inserter

Modular Material: Plastic modular conveyor belt made of POM material, with a belt thickness of 12.5mm. Modular Support: High molecular weight polyethylene wear-resistant strips + high-quality multi-layer board support. Equipment Material: 4mm Q235A hot plate laser cut and bent, with surface treatment of paint or spray treatment. Support Feet: Square tube cut and welded, made of Q235A plate welding, adjustable height ±50mm. Motor Power: 1.5KW-4.5KW Motor Brand: Guomao, China. Load Capacity: 2500KG/unit. . Frequency conversion control, maximum 25m/min. Control Program: Self-developed PLC program for automatic control, with photoelectric switch at the end of the conveyor for anti-fall protection

RELATED PRODUCT

Consultation and Quotation

-

ESTAR GROUP

No.8407,Hutai Road,Baoshan District,Shanghai,China

WhatsApp:8618616964706/8618616337720

+8618616337720