PRODUCT VIDEO

PRODUCT INTRODUCTION

PRODUCT DETAIL

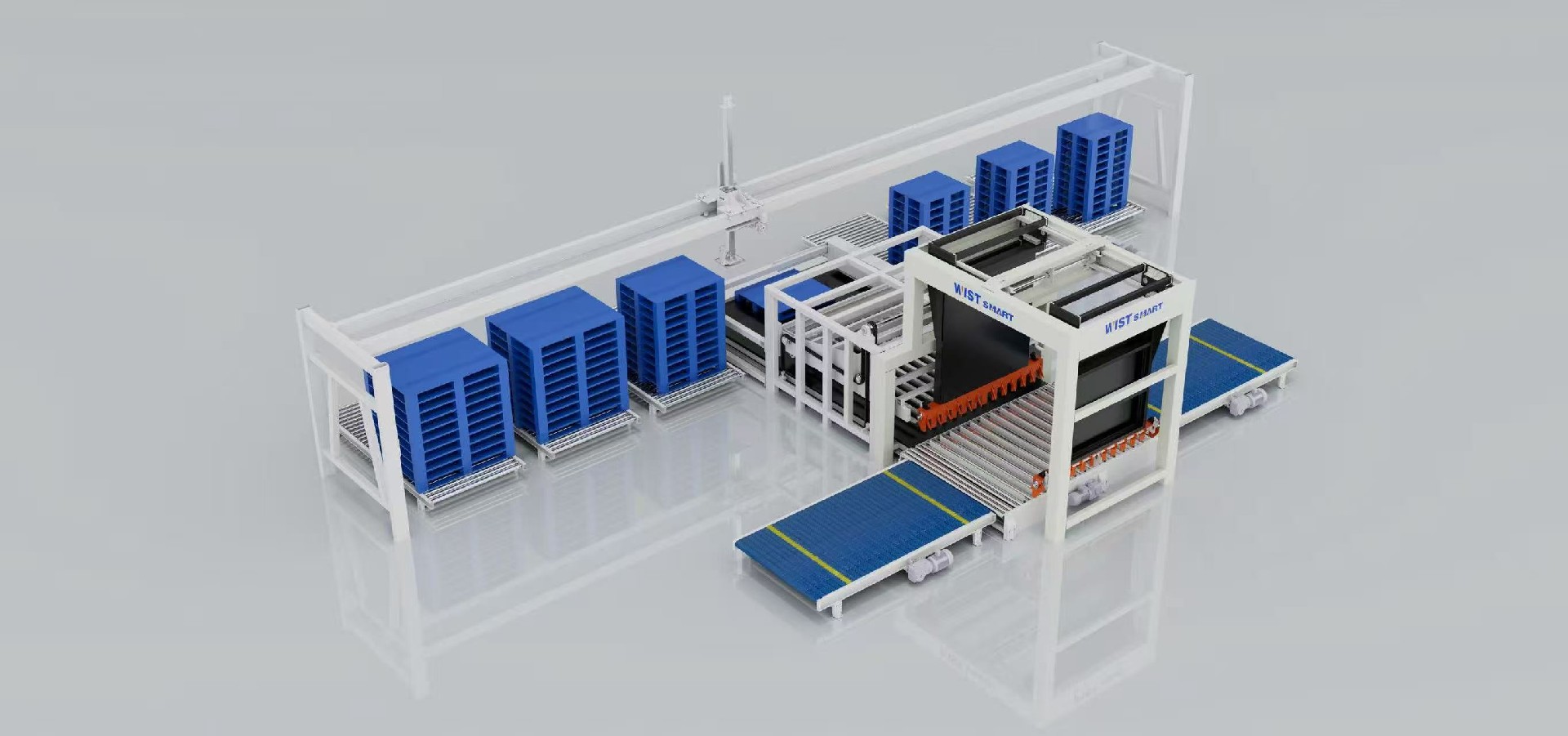

Automatic Pallet Dispenser

1. System operation planning:

• After the finished carton is palletized on each machine, the finished product is automatically transported to the pallet packaging line by conveyor line and trolley for pallet loading, arrow packing, and PE wrapping. Finally, the finished product is picked up by forklift at the end.

2. Control system description:

• It has a computer system. After manual scanning the bar code on the finished product label and connecting with the ERP/MES system, it can obtain the pallet type/arrow packing/polyethylene wrapping requirements for each stack of finished products, and then carry out the actions of stacking, packaging and wrapping.

The computer system is connected with ERP/MES system for finished product warehousing.

3. Equipment configuration description:

6 automatic pallet warehouses can store and use 6 different specifications of pallets. Each pallet same specification can be placed. The pallet storage can hold up to 1800 mm high pallet stack. 400kg Weight. A single pallet can be rotated 90 degrees when entering the palletizer to match the finished palletized configuration. Automatic stacking After the plate machine is lifted by the lifting mechanism and the multi-tooth fork mechanism, the finished product is clamped and positioned by the bilateral clamps, and the pallet is transported at the same time At the bottom center of the finished product, the fork is retracted to place the finished product smoothly on the pallet.

4. Equipment parameters:

• Finished product size: minimum 800*800, maximum 1600*1600

• Maximum finished height: minimum 600mm, maximum 2000mm

• Stacking plate size: minimum 800*800, maximum 1300*1600

• The height of the stack plate: 120mm~160mm

• The execution cycle time of the upper stack is less than 60 seconds and 60 stacks per hour.

• The pallet must be a wooden or plastic pallet with a flat bottom (three-character type or full-plane bottom).

• The overall design throughput of the line is 60 pallets per hour.

5. Major components

• PLC Siemens

• Inverter Siemens/DANFOSS Sweden

• Touch screen Siemens

• Touch screen Siemens

• Photoelectric switches XIC

• Proximity switches OMRON

• Dialing switch OMRON

Pallet Strapping Machine

Technical parameters of pallet shaft press double head strapping machine

I. Main body of the equipment

1. Conductor height: 380+/-40mm (adjustable)

2. Goods specifications and binding scope: L1200-1400 * W1000-1400 * H800-2000mm;

3. Binding method: double channel double piercing of the sword rod design, vertical binding;

4. Binding trip: the pressure plate moves up and down;

5. Lower plate pressure: 200-2000Kg adjustable;

6. Conveying line speed ≤18m/min;

7. Complete a cycle time of approximately 18 seconds, including load output, and approximately 60 pallets can be packed per hour.

8. Wellhead 90-degree lifting and rotating mechanism. Each lift

9. Packaging material: PET packaging tape;

10. The applicable packing tape specification is: width (12mm) + thickness (0.6~1.0mm);

11. Packaging paper core diameter: 406mm;

12. Packaging and belt outer diameter: 600 mm;

13. The PLC adopts the frequency converter of Siemens and Schneider of Germany, the 7-inch touch screen, the power supply of Taiwan Mingwei, the photoelectric switch of OMRON, and the relay.

14. Motor control of belt back;

15. Pre-delivery belt mechanism: belt motor control;

16. Other electrical components are imported or joint venture;

17. Item detection method: photoelectric switch detection;

18. The press plate is designed to be raised and lowered as a rack, and the press plate has the function of automatically detecting the height of goods;

19. Transmission line requirements: brake motor control;

20. Storage cart box mode: separate;

21. Mounting position of the mechanism: at the top of the pressure plate;

22. The operation table is equipped with a rotating button for sending and returning the belt, which can be very convenient to adjust the sending and returning time of the belt;

23. Packaging patterns

0x0 Auto-pass without packing

1x0 Single head for a single line

1x0+1x0 Single head for double bars

2x0 Double engine makes double stripe

24. Emergency switch is installed, which can brake immediately in emergency;

25. Body color: RAL color can be customized;

26. Noise: in the working environment, the noise is not greater than 75 decibels;

27. Environmental conditions: humidity 98%RH, temperature 0-50℃;

28. Touch screen and instruction manual: English/Portuguese;

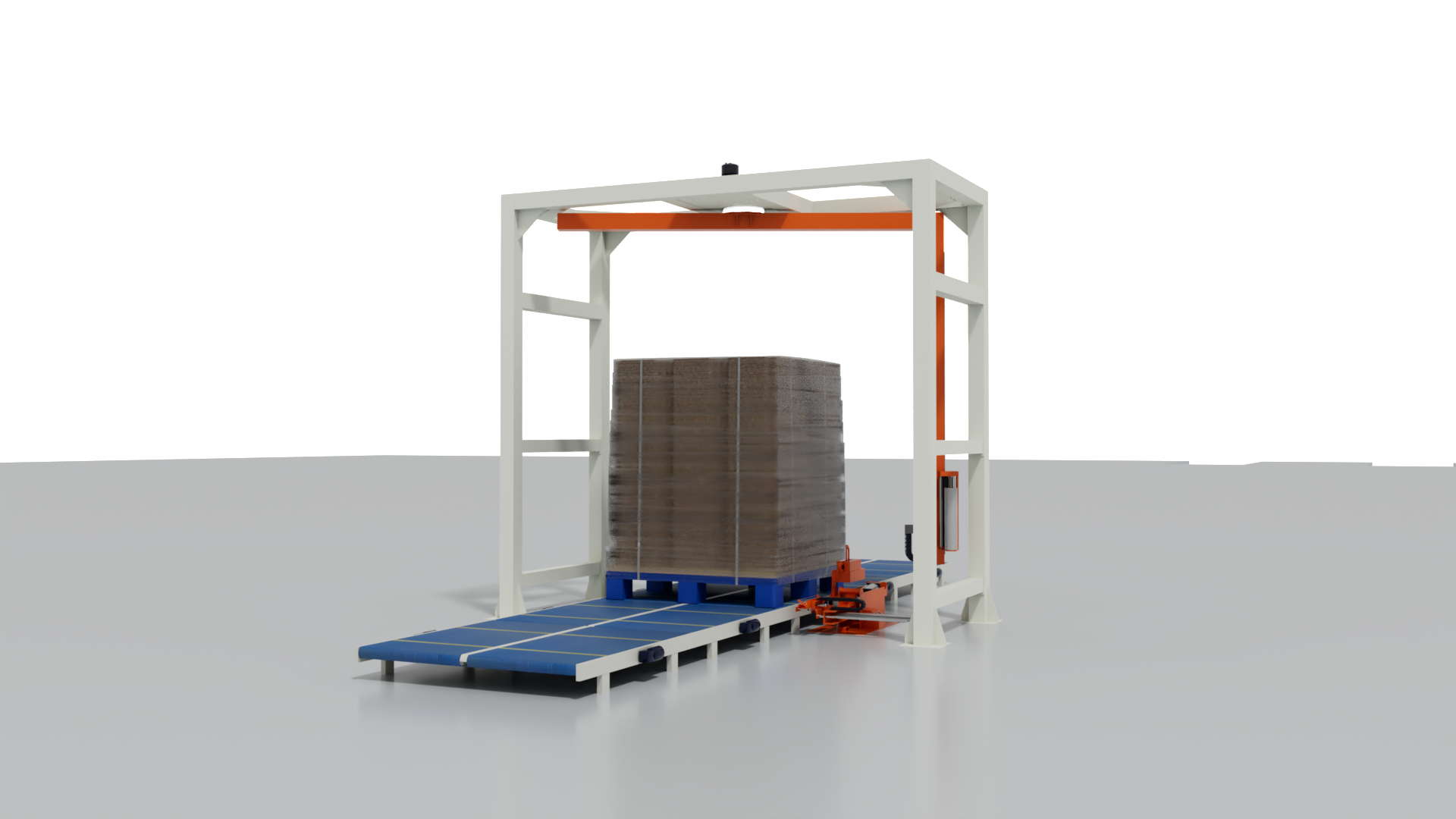

Automatic Wrapping Machine

I Product specification parameters

1. Package name: carton products stacked on pallet

2. Package size: L800-1600×W1200-1600×H1400-2000mm (including pallet) (pallet height 165mm)

3. Packaging efficiency: 20-40 pallets/hour

4. Inbound direction: The 1200mm wide side of the pallet is transported to the position where the film is wrapped

5. conveyor height: 400mm±50mm

6. Plant height: it should be more than 5 meters

III. Packaging materials

1. LLDPE stretch film:

2. Film width: 500mm

3. Thickness: 20-35μm

4. Maximum outer diameter: 260mm

5. Paper core inner hole: 76mm paper core

• Membrane frame lifting parts (1 set)

1. The lifting of the membrane frame adopts chain transmission, which is stable and reliable.

2. Type of membrane frame lifting drive reducer: turbine worm gear reducer

3, motor power: 0.37kw

4. Membrane frame lifting and deceleration motor: brand motor

• Rack components (1 set)

1. The frame is a gantry four-column square tube steel structure.

2. The upper part of the rack is equipped with a transmission bracket.

3. The rocker arm is fixed on the rocker arm frame through the rotary support.

• Automatic upper film cutting mechanism

1. Upper film: the unique upper film cutting mode, the clamping mechanism is opened, the blowing mechanism is started, and the tail of the film is automatically blown up and wrapped into the wound film;

2. Welding film, cutting film: special welding film mechanism, welding plate device and automatic cutting film program control, after cutting film automatically brush film.

3. All pneumatic components are: Airac;

• Pneumatic control system of rocker arm winding machine

1. Air source requirements: The gas used by the instrument is connected by the buyer to the inlet of the shut-off valve outside the pneumatic control box.

2. One control box controls the cylinder drive.

• Electrical and control systems

1. PLC programmable control;

2. Touch screen operation, winding layer number and frequency can be set;

3. Photoelectric switch, automatic sensing of the height of goods;

4. Rotary support drive, positioning accuracy;

5. Digital parameter setting: turntable speed, film frame lifting speed, film frame output speed (0-50 can be set);

6. The machine has automatic, manual, side conversion function, better ensure the operation of the packaging system;

7. Warning lights are set up to indicate the operation of the machine;

8. Connection function: connect to the main system through Ethernet to achieve real-time management and system integration, so as to eliminate the need for on-site configuration control computer.

RELATED PRODUCT

Consultation and Quotation

-

ESTAR GROUP

No.8407,Hutai Road,Baoshan District,Shanghai,China

WhatsApp:8618616964706/8618616337720

+8618616337720