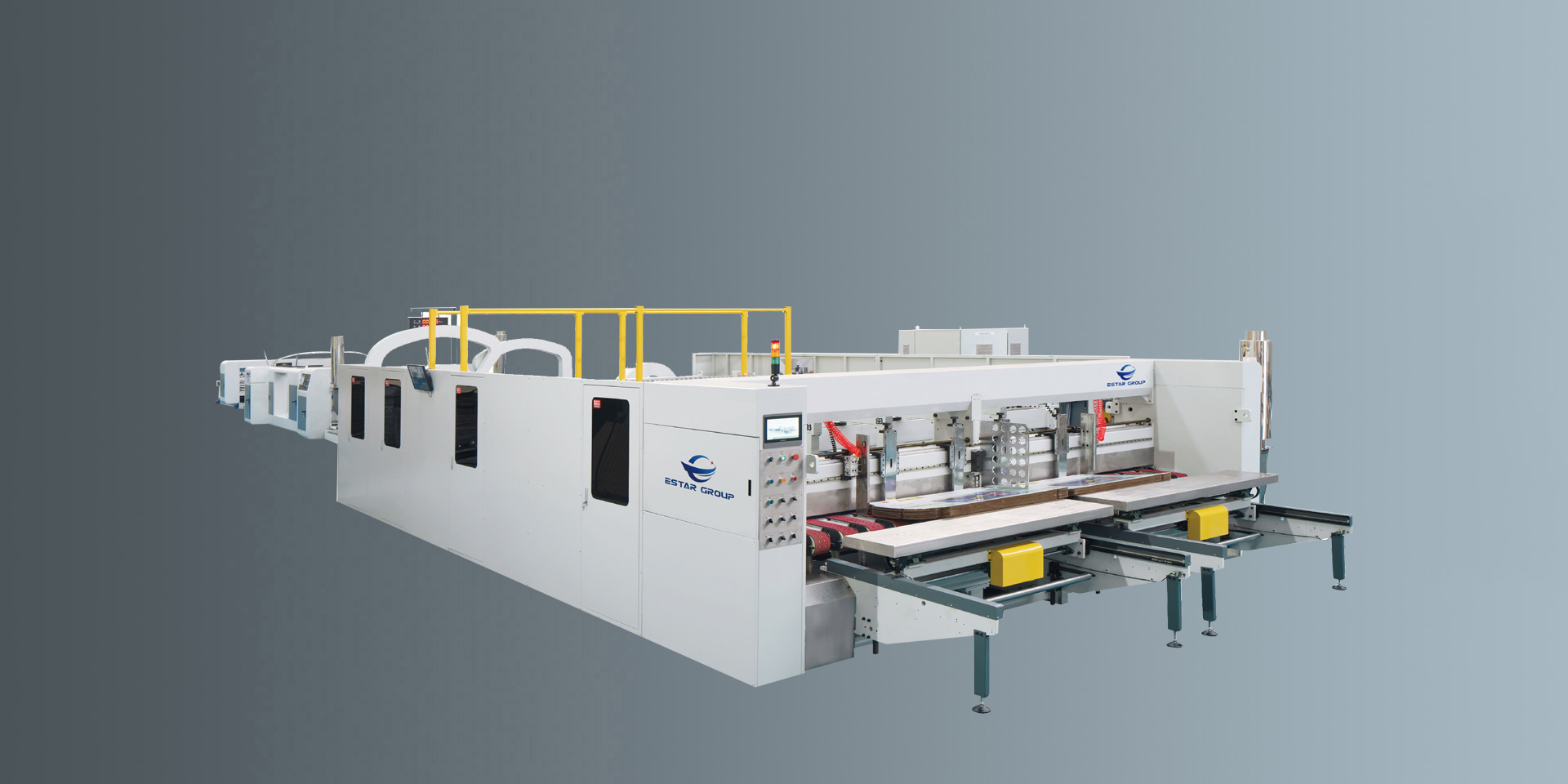

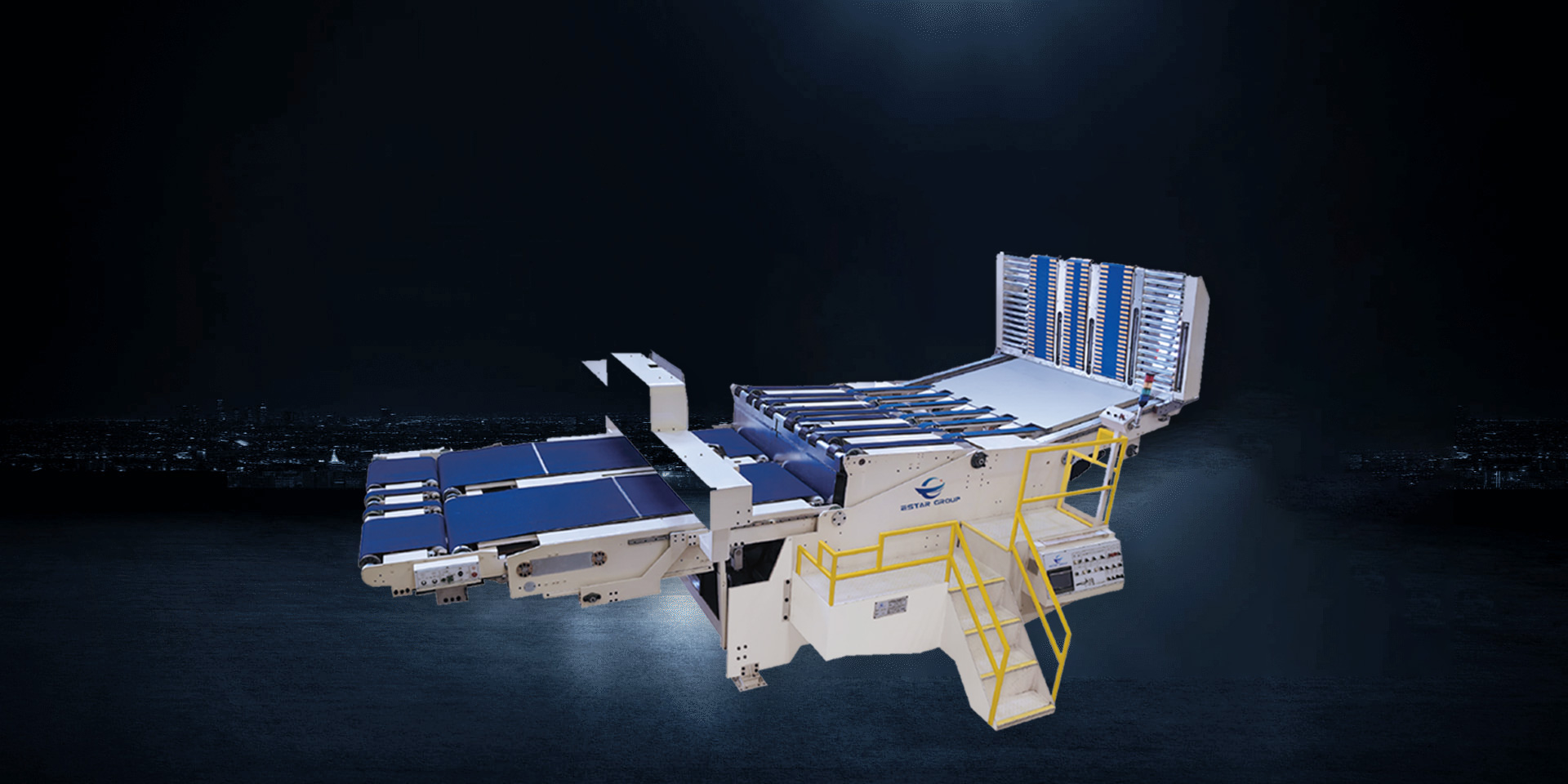

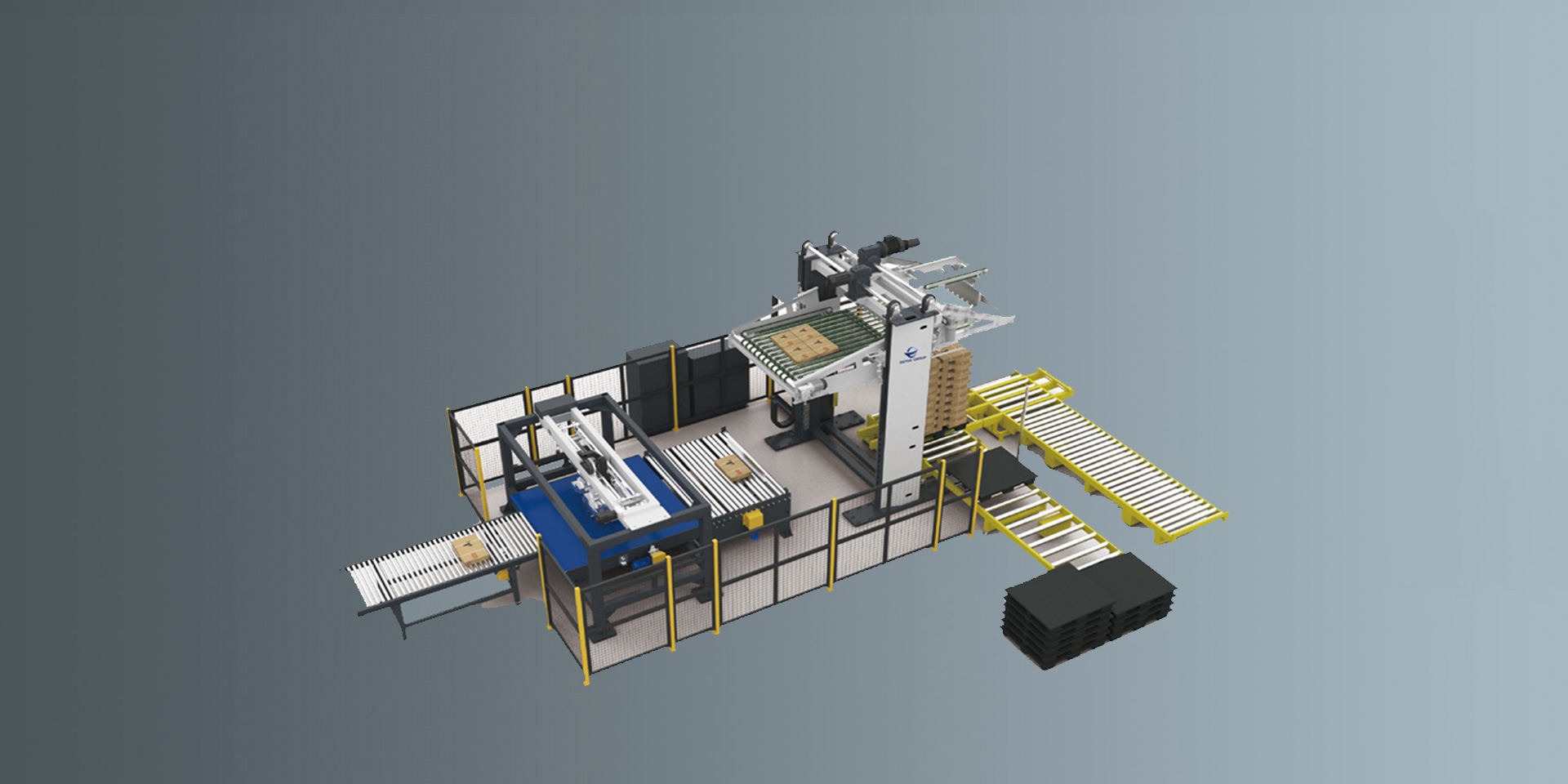

Full Automatic Packaging Solutions

-

40000+

SQUARE WORKSHOP AREA

-

1000+

COOPERATIVE CUSTOMER

-

300+

ENGINEERS

-

20+YEARS

EXPERIENCE

ESTARPACK

PRODUCT

WORLD-RENOWNED CASES

-

The Westrock Pacgaking Solution Case.

The Westrock Pacgaking Solution Case.From 2023 to 2025, Westrock has purchased several carton machines(auto prefeeder,palletizer) from estar-group.After WestRock introduced our carton equipments, they said our machine brought them the following comprehensive benefits:

1. Core benefits: cost reduction, efficiency improvement and return on investment.

2. Quality and Safety: Reducing Risks and Losses

3. Strategy and Digital Value: Empowering the Factory of the Future

-

The Modern Packaging Solution Case

The Modern Packaging Solution CaseFrom 2019 to 2025, Modern Ambalaj has purchased many carton machines from estar-group.

Like: automatic folder gluer/stitcher machine,automatic flexo printer inline folder gluer and auto prefeeder....

They said Our machines help them:

1. Significantly reduce labor costs.

2. Maximize operational efficiency and productivity.

3. Optimize space utilization and layout. Significantly reduce product loss rate.

4. Completely eliminate the risk of work-related injuries and related costs.

5. Seamless integration of intelligent logistics systems.

6. Enhance corporate image and market competitiveness.

-

The Tri-Wall Packaging Solution Case.

The Tri-Wall Packaging Solution Case.From 2018-2025,Tri-wall purchased carton machines(automatic folder gluer/stitcher machine,strapping machine,flexo printer...) from estar-group.

After Tri-wall introduced our carton machines, our machines brought them the following comprehensive benefits:

1. Direct economic benefits and cost savings.Production efficiency increased by 200%

2. A leap forward in product quality and consistency.Quality consistency reached nearly 100%

3. Operational Management and Strategic Advantages.Labor cost reduced by 70%,Customer complaint rate decreased by over 95%.

-

The KIPAS-KAGIT Packaging Solution Case

The KIPAS-KAGIT Packaging Solution CaseFrom 2019-2024,Turkey Kipas purchased carton machines(automatic folder gluer/stitcher machine,strapping machine) from estar-group.

our machines brought them the following comprehensive benefits:

1. Significantly reduce dependence on skilled workers and labor costs.

2. Extremely improve production efficiency and capacity.

3. Significantly reduce consumables and maintenance costs

4. Achieve perfect uniformity in stitching carton quality

5. Greatly reduce the risk of customer complaints and returns

6. Meet the stringent standards of high-end customers and export products

7. Strengthen market competitiveness and leadership position

-

The Smurfit Westrock Pacgaging Solution Case

The Smurfit Westrock Pacgaging Solution CaseFrom 2024-2025 Smurfit westrock purchased carton machines,(auto prefeeder,bundle-break )from Estar-Group.

They said Our machines help them :

1.Maximize operational efficiency and productivity.

2.The bundle-break maintains a constant speed, never fatigues, and can consistently operate at peak speed, completely eliminating cardboard break bottlenecks at the back end of the production line and ensuring a smooth, unimpeded production process.

3.The auto prefeeder Reduce dependence on skilled workers and labor costs and improve production efficiency and capacity.

-

The SCGP Packaging Solution Case

The SCGP Packaging Solution CaseEstar-group supplied full packaging solution for SCGP ,they purchased the whole factory carton machines from estar-group from 2018 to 2025.

The CEO of SCGP said we purchase of a complete corrugated box plant from estar-group will deliver comprehensive, transformative benefits:

1. Strategic Benefits: Reshaping Market Competitiveness

2. Operational Benefits: Peak Intelligence and Efficiency

3. Cost and financial benefits

Providing full packaging solution to SCGP has strategic, global and disruptive benefits. It has enabled SCGP to achieve a leap from "a large carton factory" to "the absolute definer of cost and quality in the regional market."

WHY CHOOSE US?

-

Technological leadership and innovation capabilitiesCustomer pain points: unstable equipment performance, low efficiency, outdated technology, and inability to produce high-difficulty orders,like:heavy duty,jumbo size and TV boxes creasing,gluing and stitching problems.What do we have:1.We hold over 40 national technical patents and more than 20 yea

Technological leadership and innovation capabilitiesCustomer pain points: unstable equipment performance, low efficiency, outdated technology, and inability to produce high-difficulty orders,like:heavy duty,jumbo size and TV boxes creasing,gluing and stitching problems.What do we have:1.We hold over 40 national technical patents and more than 20 yea -

Excellent and stable product quality and durabilityCustomer pain points: Frequent equipment failures, high downtime and maintenance rate, short service life, and rapid decline in accuracy over time.What do we have :1.We have several processing centers and Core components (such as corrugating rollers and pressure rollers) are made of special steel imported from Europe. They undergo CNC precision machining and special heat treatment processes, increasing wear resistance by three times and come with a lifetime warranty.2.Every piece of equipment undergoes a rigorous quality control process before it leaves the factory.

Excellent and stable product quality and durabilityCustomer pain points: Frequent equipment failures, high downtime and maintenance rate, short service life, and rapid decline in accuracy over time.What do we have :1.We have several processing centers and Core components (such as corrugating rollers and pressure rollers) are made of special steel imported from Europe. They undergo CNC precision machining and special heat treatment processes, increasing wear resistance by three times and come with a lifetime warranty.2.Every piece of equipment undergoes a rigorous quality control process before it leaves the factory. -

Comprehensive after-sales service systemCustomer pain points: Unable to find anyone when problems arise, slow maintenance response, long waiting time for spare parts, weak overseas technical support.What do we do:1.We have strong agents in almost every region,which make us promise:Global 24*7 online technical support, providing multi-language services in Chinese, English, Spanish, etc. Engineers will be available on-site within 72 hours in Asia and 120 hours in Europe and America.2.We maintain a global central spare parts warehouse with sufficient inventory of commonly used spare parts, ensuring timely delivery and minimizing downtime losses.

Comprehensive after-sales service systemCustomer pain points: Unable to find anyone when problems arise, slow maintenance response, long waiting time for spare parts, weak overseas technical support.What do we do:1.We have strong agents in almost every region,which make us promise:Global 24*7 online technical support, providing multi-language services in Chinese, English, Spanish, etc. Engineers will be available on-site within 72 hours in Asia and 120 hours in Europe and America.2.We maintain a global central spare parts warehouse with sufficient inventory of commonly used spare parts, ensuring timely delivery and minimizing downtime losses. -

Rich industry experience and successful casesCustomer pain points: Worry that the supplier is a novice, has no relevant industry experience, and cannot understand my production needs.What do we have:1.With over 20 years of experience in the corrugated equipment industry, we've served over 300 customers and exported our products to 40 countries.

Rich industry experience and successful casesCustomer pain points: Worry that the supplier is a novice, has no relevant industry experience, and cannot understand my production needs.What do we have:1.With over 20 years of experience in the corrugated equipment industry, we've served over 300 customers and exported our products to 40 countries. -

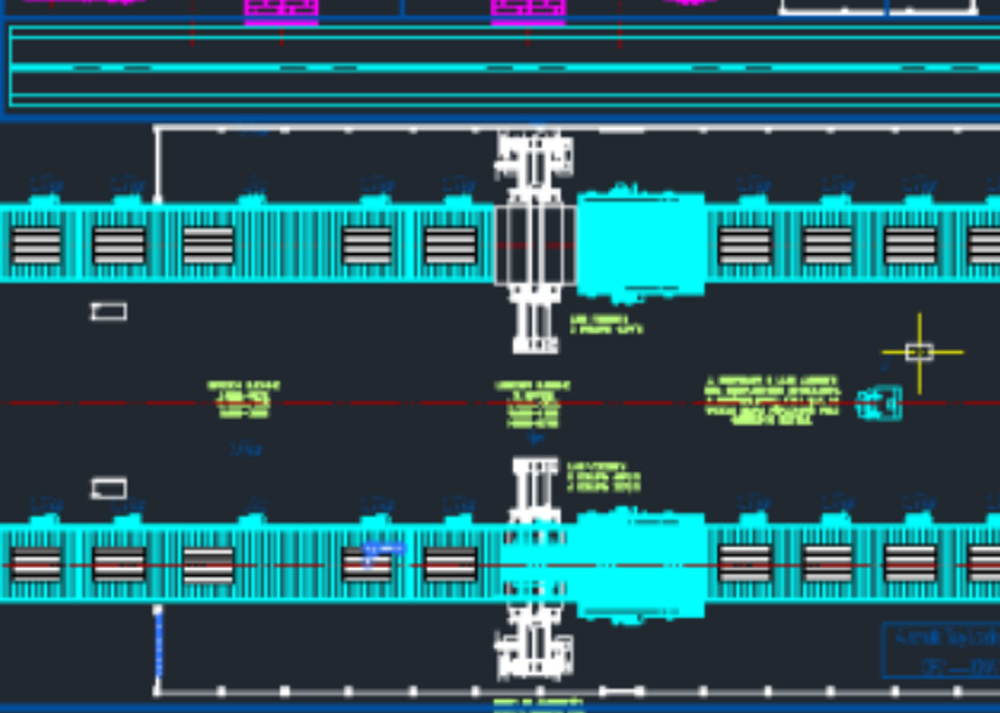

Customized solution capabilitiesCustomer pain points: My factory space is limited/I have special process requirements/I want to automate the transformation in stages, and standard equipment cannot meet the requirements.What do we have:1.We go beyond simply selling equipment; we provide one-stop, customized solutions, from plant planning and equipment selection to process design and installation and commissioning.3.We offer modular design and flexible production solutions tailored to your site, budget, and product mix.

Customized solution capabilitiesCustomer pain points: My factory space is limited/I have special process requirements/I want to automate the transformation in stages, and standard equipment cannot meet the requirements.What do we have:1.We go beyond simply selling equipment; we provide one-stop, customized solutions, from plant planning and equipment selection to process design and installation and commissioning.3.We offer modular design and flexible production solutions tailored to your site, budget, and product mix. -

High cost performance and return on investmentCustomer pain points: limited budget, concerns about long investment return cycle, and high overall usage costs (energy consumption, labor, and waste).What do we do:1.While the initial investment is 25% higher than the industry average, your investment can be recovered within 18 months through 20% energy savings, 50% labor savings, and 25% waste reduction.2.Flexible financing options (financial leasing) are available to alleviate your initial capital pressure.

High cost performance and return on investmentCustomer pain points: limited budget, concerns about long investment return cycle, and high overall usage costs (energy consumption, labor, and waste).What do we do:1.While the initial investment is 25% higher than the industry average, your investment can be recovered within 18 months through 20% energy savings, 50% labor savings, and 25% waste reduction.2.Flexible financing options (financial leasing) are available to alleviate your initial capital pressure.

VIDEO

NEWS

Consultation and Quotation

-

ESTAR GROUP

No.8407,Hutai Road,Baoshan District,Shanghai,China

WhatsApp:8618616964706/8618616337720

+8618616337720